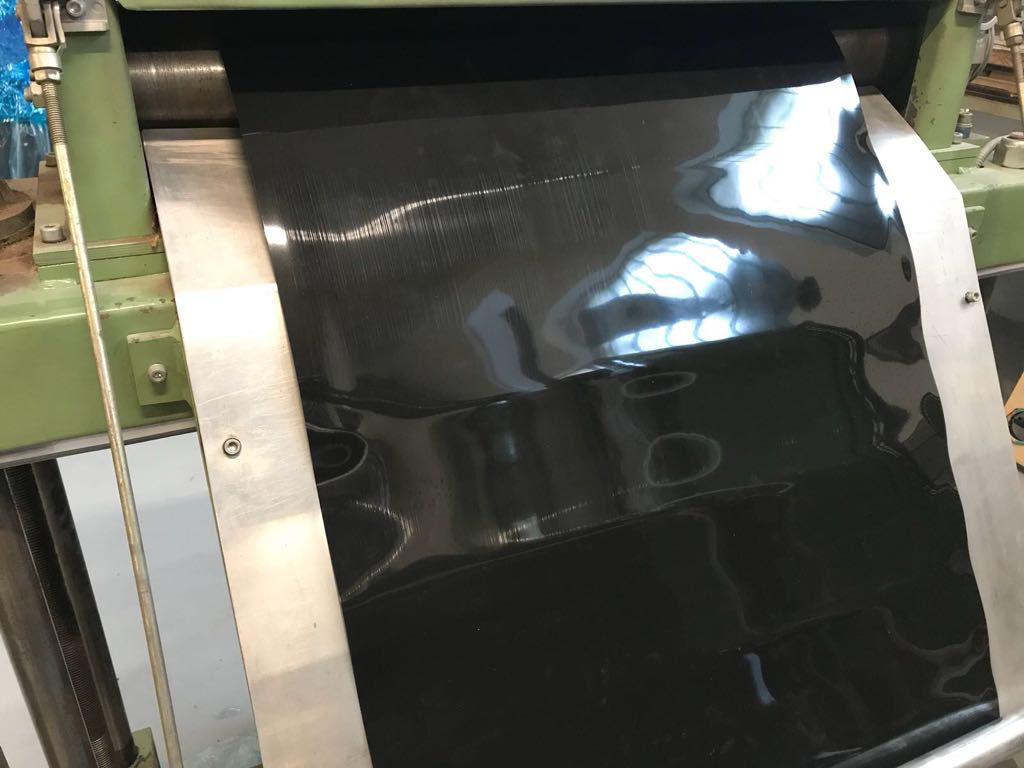

Carbon Nemo Company was born in 2009 and focuses its activity mainly on the thermoforming of PET / PS / PS flocked films. The company is subdivided into its area of design, production and storage of goods. This plastic film, the company’s protagonist, runs through rollers that bring the material to a high temperature, so that it can be modeled. Afterwards, the molds of the product to be realized come into play. The “soft” molded material, positioned on the molds (designed and manufactured directly in the company thanks to a CNC machine) takes that shape. Then it is cooled and finally baked resulting from this process, as a final product, the finished blister.

The company generally follows every stage of production from design to completion of the finished product. It goes from the idea of an article to the drawing, then comes to the realization of the prototype to be used as a mold to get to the product. Business relations with customers are managed by the owner himself, by the foreign trade manager and by several representatives operating in the territory.